운영 목적

외국인을 대상으로 단기 기술 교육 프로그램을 운영하여 대학의 대내외 홍보를 강화하고, 국제 교류를 활성화하며 경쟁력 있는 국제 교육 프로그램의 운영과 확대를 목표로 합니다.

실습 중심 교육

-

Real Industry

EducationApplied course for Hyundai Motors Employee educational program High-level Hands on Courses

-

For everyone

Preliminary knowledge in Electronics, Software or Coding is not required Course materials are provided for everyone

-

Test your

limitWith new skill sets, improve the performance of your car Test your car performance

-

Lectures

For each Lesson, a professor will be designated Also, course assistant will be there to help

프로그램 세부내용

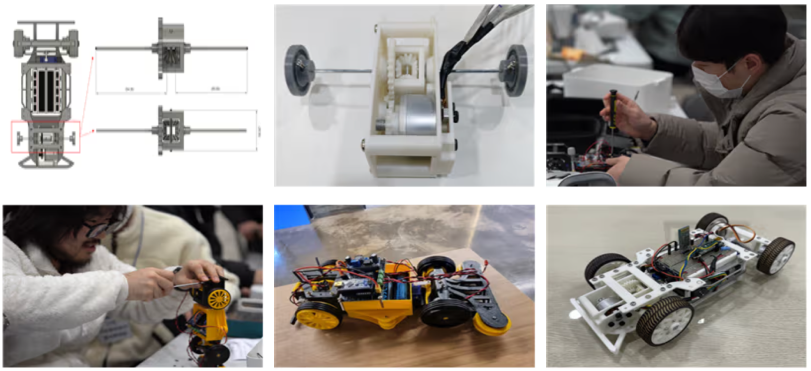

글로벌 국제 교육 프로그램의 일환으로 3D 프린팅을 활용한 전기차 제작 종합 과정을 제공합니다. 이 프로그램은 학생들이 전기차 부품의 설계, 프린팅, 조립 과정을 직접 체험할 수 있는 실습 중심의 학습 기회를 제공합니다. 아래에서 각 세션의 세부 일정과 주제를 확인하실 수 있습니다.

Hardwares

Electric Vehicle Design and Production Using 3D Modeling and Printing

Electric Circuits & Coding

Build Electric Circuits and Assemble an Electric Vehicle

Camera Settings & Improvement

FPV Camera Setting and Improving Electric Vehicle Performance

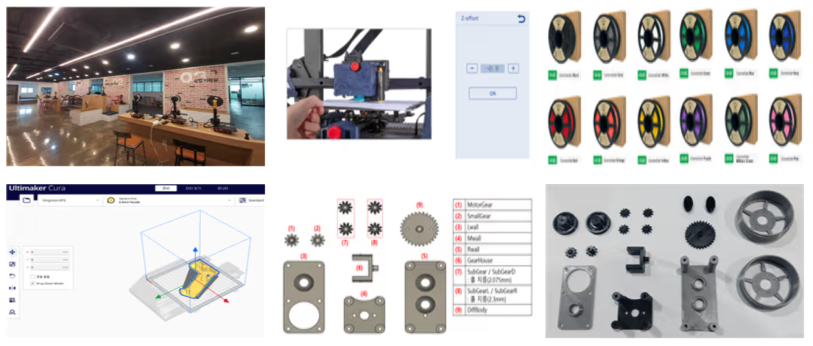

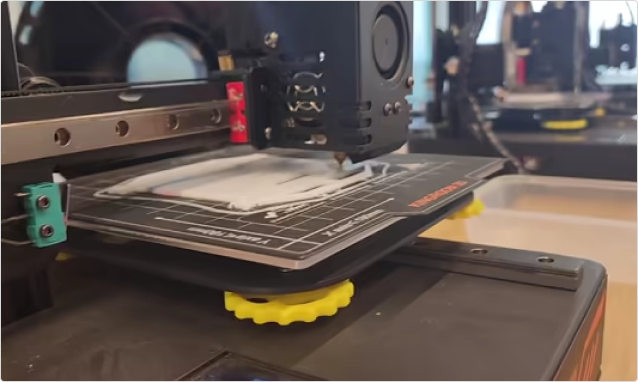

DAY 1. 3D Printing Basics

| Method | Materials Needed | Topics Covered |

|---|---|---|

| Theory / Practice | Electric Car Kit (electric circuits, controllers, tools) |

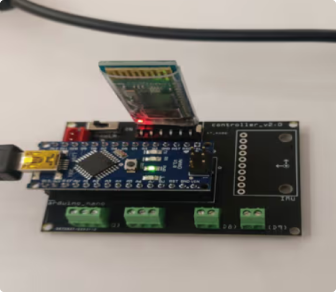

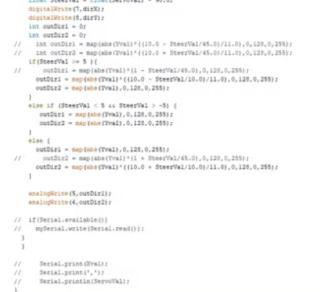

Theory behind powertrain for electric vehicles Wireless communication setup (vehicle, controller) Wiring and connecting electric circuits (vehicle, controller) / PCB version Coding (for vehicle control) |

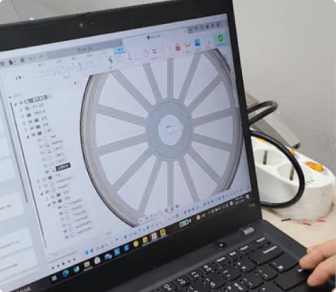

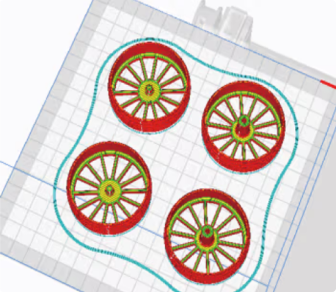

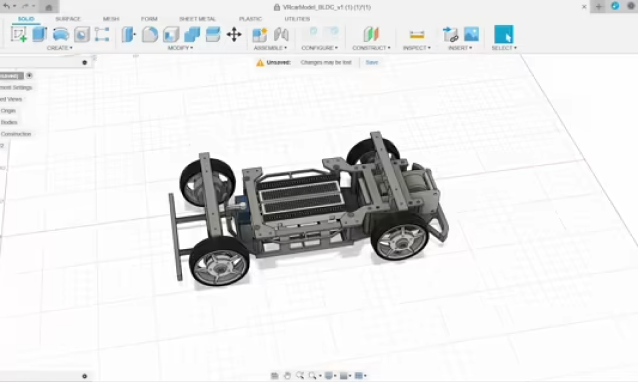

DAY 2. Modifying 3D Models and 3D Printing the Car Partss

| Method | Materials Needed | Topics Covered |

|---|---|---|

| Theory / Practice | 3D printer, filament, laptop (with Fusion360, Cura, and Arduino installed) |

Creating 3D models of car parts using Fusion360 Designing and printing a bumper Designing and printing a camera mount Improving electric car parts design |

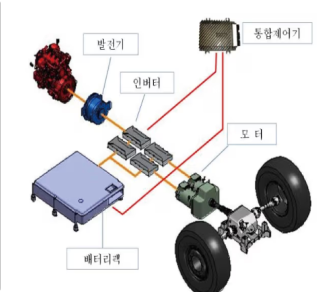

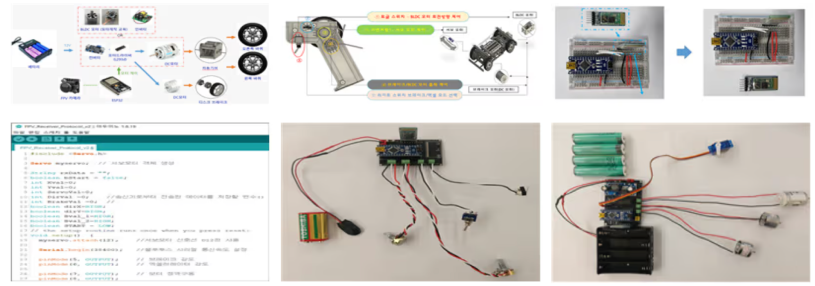

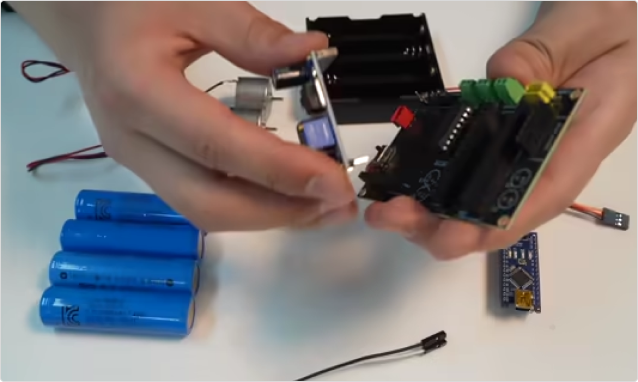

DAY 3. Powertrain and Circuit Design Practice

| Method | Materials Needed | Topics Covered |

|---|---|---|

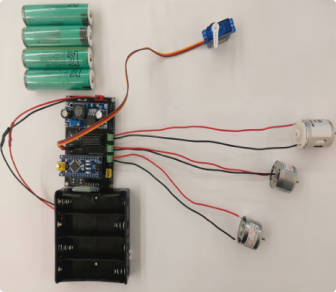

| Theory / Practice | Electric Car Kit (electric circuits, controllers, tools) |

Theory behind powertrain for electric vehicles Wireless communication setup (vehicle, controller) Wiring and connecting electric circuits (vehicle, controller) / PCB version Coding (for vehicle control) |

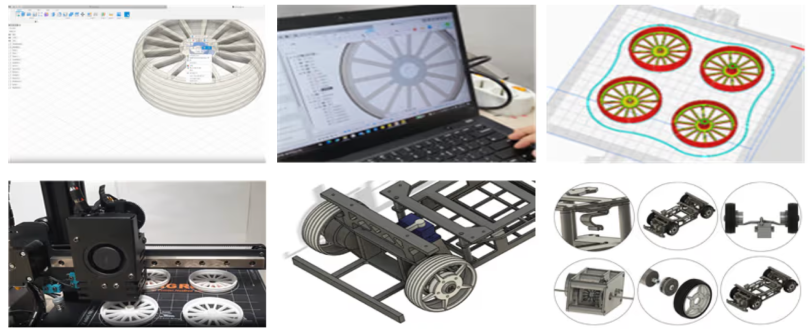

DAY 4. Assembling Vehicle Hardware

| Method | Materials Needed | Topics Covered |

|---|---|---|

| Theory / Practice | 3D Printed Outputs (Chassis, Differential Gear, Disc Brake, Controller) |

Understanding and Creating Electric Car Hardware Assembling Differential Gears Assembling Disc Brakes Assembling Chassis Frames Completing Electric Car Assembly (Hardware + Circuit) |

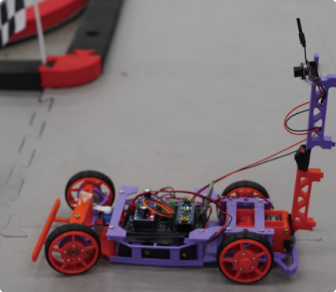

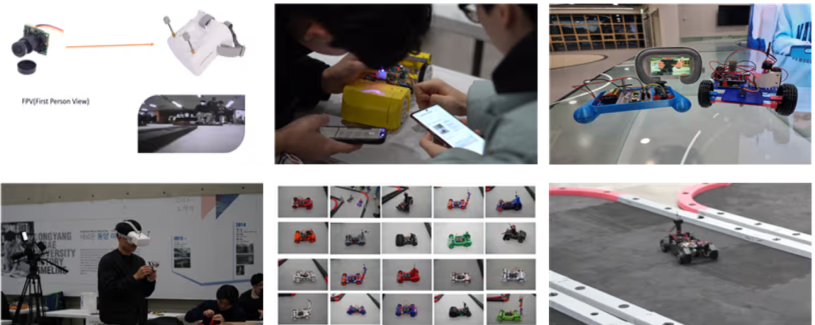

DAY 5. FPV Setup for Remote Driving and Test Runs

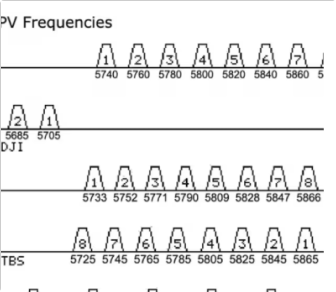

| Method | Materials Needed | Topics Covered |

|---|---|---|

| Theory / Practice | FPV goggle, FPV camera | Setting up FPV (Goggles / Camera) Changing FPV Camera Channels Selecting the Optimal Camera Position on the Vehicle Driving Practice Debugging and Identifying Areas for Improvement |

DAY 6. Improving Vehicle Performance

| Method | Materials Needed | Topics Covered |

|---|---|---|

| Theory / Practice | Previously provided materials | Driving Practice Using FPV Remote Control Improving Electric Car Performance (Electric circuits, Hardware, Coding) |

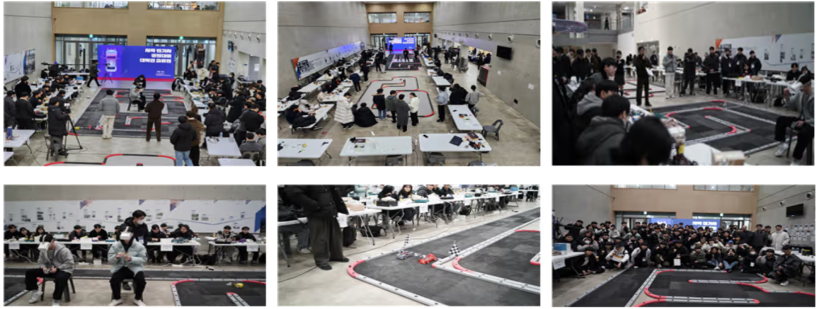

DAY 7. Racing Competition

| Method | Materials Needed | Topics Covered |

|---|---|---|

| Theory / Practice | Previously provided materials | Electric Car Competition Using FPV Remote Control Preliminary Round: Individual Driving (Time Trials) Final Round: 1-on-1 Driving (Tournament) |

DAY 8. Self-driving Car Racing Competition

| Method | Materials Needed | Topics Covered |

|---|---|---|

| Theory / Practice | Controller, electric circuits, SD card | Deep learning theory Image-Based Model Training Behavior Cloning for Autonomous Driving Drive Missions (Driving, Traffic Lights, Obstacle Avoidance, Parking) Competition (Autonomous Driving Racing) |